Mobile Hydraulics and Controls for a Rail Car Heating System in the Railroad Equipment Industry | article published in the Fluid Power Journal March 2025

This article was published in the Fluid Power Journal

in March 2025.

The Role of Mobile Hydraulics in Rail Heating Systems

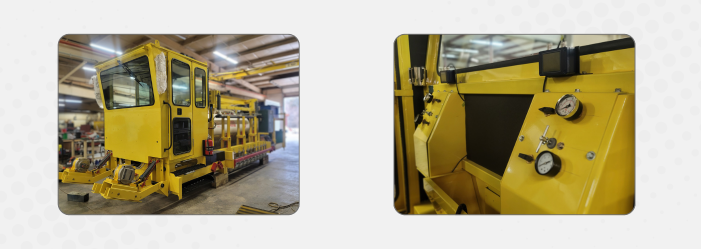

To achieve the precise range of speeds and torque required for heating rails, a combination of hydrostatic drive and mechanical linkage systems was deployed. This setup ensures sufficient power to move the system across the rails at controlled speeds, even on inclines. Additionally, an auxiliary pressure-compensated, load-sensing circuit operates ancillary equipment, such as burner assemblies, blower fans, and vibratory mechanisms.

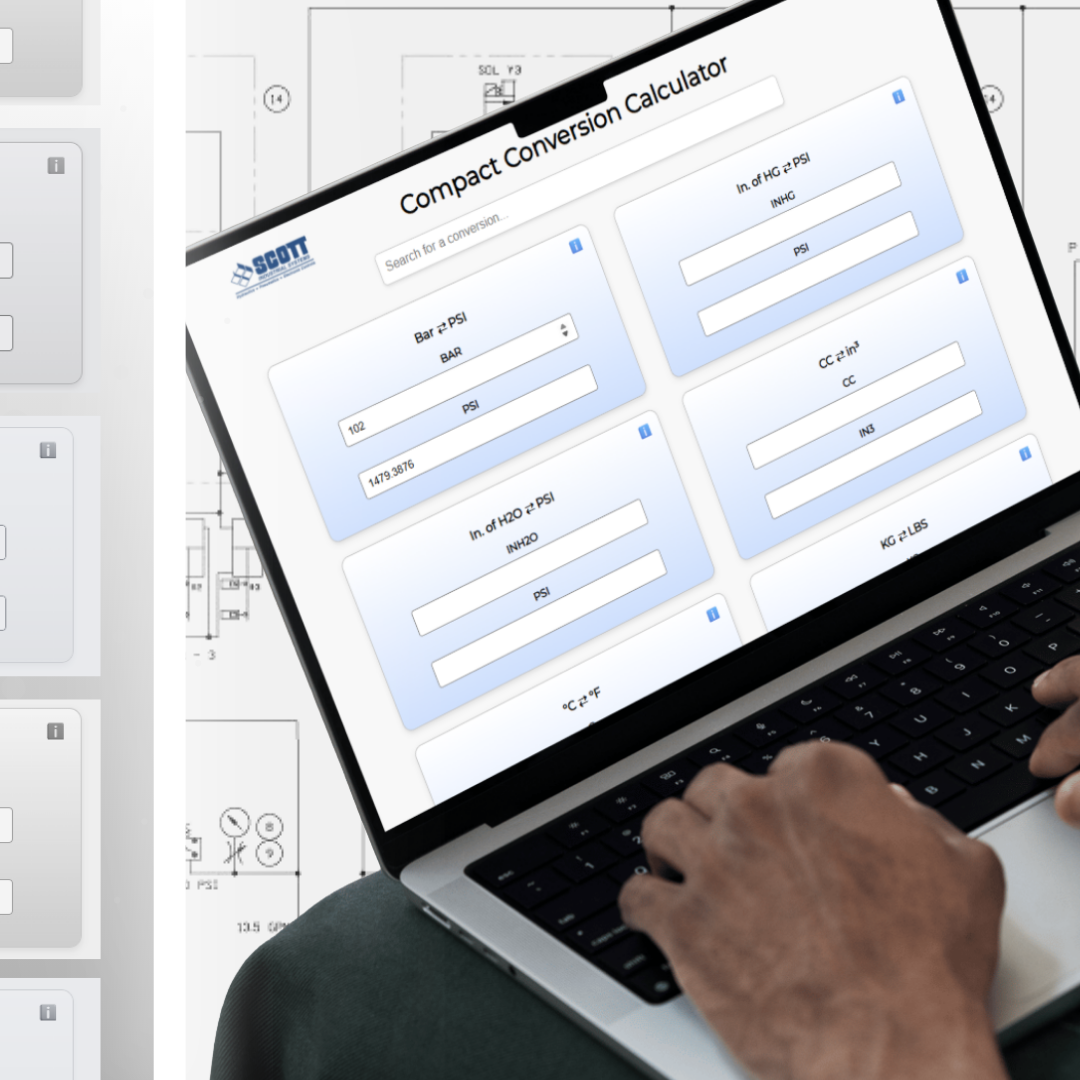

The system’s hydraulic components include a hydrostatic pump with PWM (Pulse Width Modulation) control, radial piston motors for the main drive system or vehicle propel function. Pressure-compensated piston pumps are used to supply hydraulic power to the auxiliary functions, while directional control valves, both cartridge-style and sectional-style, manage the hydraulic flow. These components, paired with a robust mobile control module, create a hydraulic and control system capable of thriving in harsh outdoor environments.

Control System Operation and Design

The control system is built around a durable mobile PLC control module programmed with software developed using the CoDeSys environment. This module interfaces with the directional control valves through wired communication and with the diesel engine via the J1939 CAN bus protocol. Sensors, both analog and digital, provide real-time data for monitoring system performance. This design ensures reliable operation, even in extreme conditions.

Challenges in the Field

One of the primary challenges faced by rail heating systems is operating in severe outdoor environments with minimal downtime. These machines often function in remote areas across North America, where resources for repairs and troubleshooting are limited. Downtime can halt an entire segment of the railroad system, making simplicity and reliability paramount. The system’s design prioritizes ease of maintenance, allowing field technicians to quickly identify and address issues.

Heating System Configurations

The rail heating system comes in two configurations: propane-powered and diesel-powered. The propane system requires controlled propane flow, while the diesel system uses a fan/blower assembly with a closed-loop control system to maintain consistent airflow. Both systems feature independent burner banks to heat each side of the rail, ensuring uniform temperature distribution.

Innovative Features

The rail heating system incorporates several innovative features, including a cruise control function that enables precise speed control. In work mode, the rail car system operates at speeds as low as 1/8 MPH, a capability unique to the industry. This slow, steady speed is critical for effective rail heating. Additionally, transport mode allows speeds of up to 20 MPH for relocating the equipment. Operator controls include an electronic joystick for speed and directional adjustments, along with comprehensive system monitoring and fault indicators for troubleshooting.

Safety Measures

Safety is a key consideration in the system’s design. Real-time monitoring ensures optimal fluid levels and temperatures, while built-in shutdown mechanisms protect against low or overheated conditions. The system also includes "driver presence" technology, preventing the machine from operating in an unmanned state.

Ease of Maintenance

Maintenance is facilitated by detailed operator manuals, on-site training, and diagnostic tools such as test points and fault indicators. These features enable railroad industry technicians to efficiently service the equipment and minimize downtime. The system’s simplicity and robustness are essential for reliable operation in remote and challenging environments.

Historical Context and Evolution

The concept of rail heating systems dates to the 1950s, when mechanical technology was used to perform the task. Since the early 2000s, advancements in hydraulics and electronic controls have revolutionized these systems, providing greater efficiency, reliability, and precision. Modern designs, operational for over 15 years, continue to set the standard in the industry.

Energy Efficiency and Environmental Considerations

The closed-loop hydrostatic drive system improves fuel efficiency by reducing waste, allowing longer operating durations before refueling. In the diesel-powered configuration, the shared fuel system between the engine and burners further enhances efficiency. These features contribute to a more sustainable approach to rail heating.

Conclusion

Mobile hydraulics and control systems have transformed rail heating in the railroad industry. By combining advanced hydraulic technology, innovative control features, and robust safety measures, these systems ensure reliable operation in even the harshest environments. Their efficiency, simplicity, and adaptability make them indispensable tools for maintaining the stability and safety of railroad infrastructure. As the industry continues to evolve, these systems will remain at the forefront of technological advancements, meeting the demands of modern rail operations.

Written by Kevin Smith, Vice President of Sales, SCOTT Industrial Systems

Hydraulic oil cleanliness is critical to industrial performance. In automotive plastics manufacturing, contaminated oil can lead to costly downtime, frequent maintenance, and reduced equipment lifespan. One U.S.-based manufacturer faced this exact challenge - until a more brilliant filtration strategy transformed their operations. 👉 VIEW THE CASE STUDY The Problem: Contaminated Hydraulic Oil Disrupts Production This manufacturer’s molding presses were operating with dangerously high contamination levels, with oil testing at ISO 24/23/21. Their existing filter elements , despite being from a well-known brand, failed to deliver consistent performance. The issues included: Low dirt-holding capacity Frequent filter replacements Hard-to-access filter locations Increased risk of hydraulic failure These inefficiencies drove up maintenance costs and caused repeated production delays. The Solution: Partnering for Smarter Filtration To address the issue, Scott Industrial Systems teamed up with Schroeder Industries to implement a high-efficiency, cost-effective filtration strategy. The collaboration focused on both lab validation and real-world application to ensure long-term success. Key Actions Taken: Conducted side-by-side lab testing of filter elements Introduced multi-layer filtration technology Deployed Total Fluid Condition testing, filter carts, and duplex assemblies Replaced old filters with Schroeder elements (3µm, 5µm, 10µm) Upgraded dehydrator filters for system-wide consistency The Results: Cleaner Oil, Better Performance The impact was immediate. Oil cleanliness improved to ISO 16/14/11, leading to: Reduced maintenance frequency Fewer hydraulic failures Improved equipment uptime Lower overall operating costs The success of this solution led to its adoption across multiple facilities, setting a new internal standard for hydraulic oil cleanliness. Why It Matters Upgrading to high-performance filtration systems doesn’t just protect your equipment; it also drives efficiency, reliability, and cost savings. This case study proves that more innovative filtration can be a game-changer for manufacturers relying on hydraulic systems. SCOTT delivers more than just components - we provide comprehensive fluid power solutions backed by rigorous testing, validation, and proven results. 👉 Ready to improve your hydraulic oil performance? Contact our team today to learn more about our filtration solutions.

Scott Industrial Systems announces the acquisition of Automated Engineered Solutions (AES), an automation company headquartered in Oberlin, Ohio. This marks a significant milestone in SCOTT’s continued growth, deepening its expertise in industrial automation, custom machinery, & advanced engineering solutions.

Pneumatics have played a crucial role in the evolution of aviation, dating back to the early 20th century. By the 1920s and 1930s, as aircraft design advanced rapidly, pneumatic systems emerged as a practical solution for enhancing performance and reliability, especially when weight was a critical factor.

In today’s fast-paced manufacturing world, automation plays a crucial role in improving efficiency and reducing manual labor. Jasper Engines & Transmissions, a leader in remanufacturing powertrain components, faced a challenge in optimizing the removal of lifter plungers from a family of internal combustion engines.