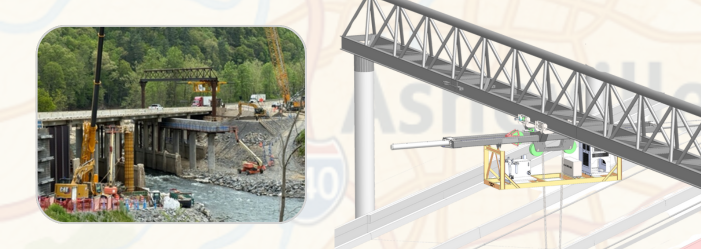

Scheduled Bridge Replacement on Interstate 40: SCOTT Hydraulic Solutions in Action

Case Study: Girder Gantry System

A major infrastructure upgrade was underway near Asheville, North Carolina, where a key section of Interstate 40 is being replaced to ensure long-term reliability and safety for one of the region’s busiest corridors.

VIEW THE CASE STUDY

VIEW THE CASE STUDY

To support the planned bridge replacement, the end customer required a solution to lift and position large concrete girders with precision and safety. SCOTT partnered with the contractor to provide a fully integrated hydraulic and control system designed to handle the job's complexity.

The Challenge

- Operate two gantry systems in sync—one at each end of the girder

- Enable remote, precise X and Y movement during placement

- Provide real-time feedback on engine performance

- Ensure smooth coordination between hydraulic and engine control systems

Our Solution | SCOTT delivered a turnkey system featuring:

- Two diesel hydraulic power units (HPUs) equipped with PVG32 proportional valves

- MC038-10 Plus+1® controller for managing logic and system functions

- IK3 wireless radio transmitter with dual receivers for remote operation

- MPCAN modules enabling CAN bus communication for control and feedback

With one transmitter, the operator can simultaneously control both lifting machines, including engine start/stop, throttle, and valve movement. The system also provides live engine feedback on fuel level, temperature, and battery status, ensuring safe and efficient operation.

The Result

Successfully tested and ready for deployment, this system played a key role in the timely completion of the I-40 bridge replacement. The customer is highly satisfied with the performance, reliability, and ease of use.

Why It Matters

Planned infrastructure updates, such as this one, keep our highways safe, efficient, and built to last. SCOTT is proud to support critical projects with the hydraulic and control expertise to make them a success.

Hydraulic oil cleanliness is critical to industrial performance. In automotive plastics manufacturing, contaminated oil can lead to costly downtime, frequent maintenance, and reduced equipment lifespan. One U.S.-based manufacturer faced this exact challenge - until a more brilliant filtration strategy transformed their operations. 👉 VIEW THE CASE STUDY The Problem: Contaminated Hydraulic Oil Disrupts Production This manufacturer’s molding presses were operating with dangerously high contamination levels, with oil testing at ISO 24/23/21. Their existing filter elements , despite being from a well-known brand, failed to deliver consistent performance. The issues included: Low dirt-holding capacity Frequent filter replacements Hard-to-access filter locations Increased risk of hydraulic failure These inefficiencies drove up maintenance costs and caused repeated production delays. The Solution: Partnering for Smarter Filtration To address the issue, Scott Industrial Systems teamed up with Schroeder Industries to implement a high-efficiency, cost-effective filtration strategy. The collaboration focused on both lab validation and real-world application to ensure long-term success. Key Actions Taken: Conducted side-by-side lab testing of filter elements Introduced multi-layer filtration technology Deployed Total Fluid Condition testing, filter carts, and duplex assemblies Replaced old filters with Schroeder elements (3µm, 5µm, 10µm) Upgraded dehydrator filters for system-wide consistency The Results: Cleaner Oil, Better Performance The impact was immediate. Oil cleanliness improved to ISO 16/14/11, leading to: Reduced maintenance frequency Fewer hydraulic failures Improved equipment uptime Lower overall operating costs The success of this solution led to its adoption across multiple facilities, setting a new internal standard for hydraulic oil cleanliness. Why It Matters Upgrading to high-performance filtration systems doesn’t just protect your equipment; it also drives efficiency, reliability, and cost savings. This case study proves that more innovative filtration can be a game-changer for manufacturers relying on hydraulic systems. SCOTT delivers more than just components - we provide comprehensive fluid power solutions backed by rigorous testing, validation, and proven results. 👉 Ready to improve your hydraulic oil performance? Contact our team today to learn more about our filtration solutions.

Scott Industrial Systems announces the acquisition of Automated Engineered Solutions (AES), an automation company headquartered in Oberlin, Ohio. This marks a significant milestone in SCOTT’s continued growth, deepening its expertise in industrial automation, custom machinery, & advanced engineering solutions.

Pneumatics have played a crucial role in the evolution of aviation, dating back to the early 20th century. By the 1920s and 1930s, as aircraft design advanced rapidly, pneumatic systems emerged as a practical solution for enhancing performance and reliability, especially when weight was a critical factor.

In today’s fast-paced manufacturing world, automation plays a crucial role in improving efficiency and reducing manual labor. Jasper Engines & Transmissions, a leader in remanufacturing powertrain components, faced a challenge in optimizing the removal of lifter plungers from a family of internal combustion engines.