Engineered for Efficiency: Delivering Fluid Power Solutions with Danfoss

From Prototype to Production:

Visit: Danfoss supplier page, Danfoss Mobile Valve Build Center page

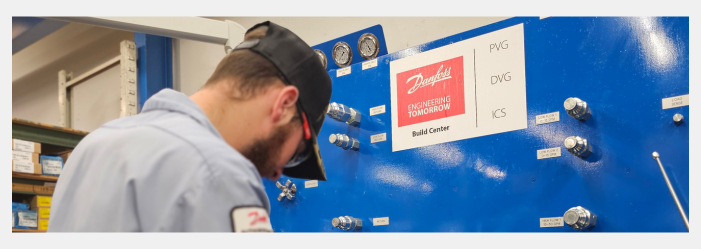

When it comes to fluid power solutions, having the right certifications and capabilities can make all the difference. That's why at Scott Industrial Systems, we take immense pride in our Danfoss Certification and Build Center. These aren't just fancy labels - they represent our unwavering commitment to excellence, precision, and rapid delivery in everything we do.

Our Danfoss certification is a testament to the high level of technical expertise our team possesses. It means we've undergone rigorous training and met stringent quality standards, so you can trust that we know our stuff inside and out. We're not just slapping parts together - we're fluid power experts who understand the intricacies of these systems and how to optimize their performance.

But it's not just about knowledge; it's also about execution. That's where our Build Center comes into play. This state-of-the-art facility allows us to provide fast turnaround times for replacement parts, production needs, and even prototype development. Whether you need an urgent repair or you're working on the next big innovation, we can deliver with speed and reliability.

Imagine this scenario: One of your critical machines goes down, and you're facing costly downtime. With our Build Center, we can quickly source the necessary parts, assemble them with precision, and get that machine back up and running in no time. Or maybe you're a design engineer working on a cutting-edge fluid power system, and you need prototypes to test and refine your concepts. We can make that happen, collaborating with you every step of the way to bring your vision to life.

At the end of the day, our Danfoss Certification and Build Center capabilities are all about delivering world-class products and services with confidence. We're not just suppliers; we're partners who understand the importance of minimizing downtime, maximizing efficiency, and driving innovation. So, whether you're facing a critical repair or embarking on a groundbreaking new project, you can count on us to exceed your expectations with speed, reliability, and performance.