Boosting Hydraulic System Efficiency with Smarter Oil Filtration:

A Case Study in Automotive Plastics Manufacturing

Hydraulic oil cleanliness is critical to industrial performance. In automotive plastics manufacturing, contaminated oil can lead to costly downtime, frequent maintenance, and reduced equipment lifespan.

One U.S.-based manufacturer faced this exact challenge - until a more brilliant filtration strategy transformed their operations.

The Problem:

Contaminated Hydraulic Oil Disrupts Production

This manufacturer’s molding presses were operating with dangerously high contamination levels, with oil testing at ISO 24/23/21. Their existing filter elements, despite being from a well-known brand, failed to deliver consistent performance.

The issues included:

The issues included:

- Low dirt-holding capacity

- Frequent filter replacements

- Hard-to-access filter locations

- Increased risk of hydraulic failure

These inefficiencies drove up maintenance costs and caused repeated production delays.

The Solution:

Partnering for Smarter Filtration

To address the issue, Scott Industrial Systems teamed up with Schroeder Industries

to implement a high-efficiency, cost-effective filtration strategy. The collaboration focused on both lab validation and real-world application to ensure long-term success.

Key Actions Taken:

- Conducted side-by-side lab testing of filter elements

- Introduced multi-layer filtration technology

- Deployed Total Fluid Condition testing, filter carts, and duplex assemblies

- Replaced old filters with Schroeder elements (3µm, 5µm, 10µm)

- Upgraded dehydrator filters for system-wide consistency

The Results: Cleaner Oil, Better Performance

The impact was immediate. Oil cleanliness improved to ISO 16/14/11, leading to:

- Reduced maintenance frequency

- Fewer hydraulic failures

- Improved equipment uptime

- Lower overall operating costs

The success of this solution led to its adoption across multiple facilities, setting a new internal standard for hydraulic oil cleanliness.

Why It Matters

Upgrading to high-performance filtration systems doesn’t just protect your equipment; it also drives efficiency, reliability, and cost savings. This case study proves that more innovative filtration can be a game-changer for manufacturers relying on hydraulic systems.

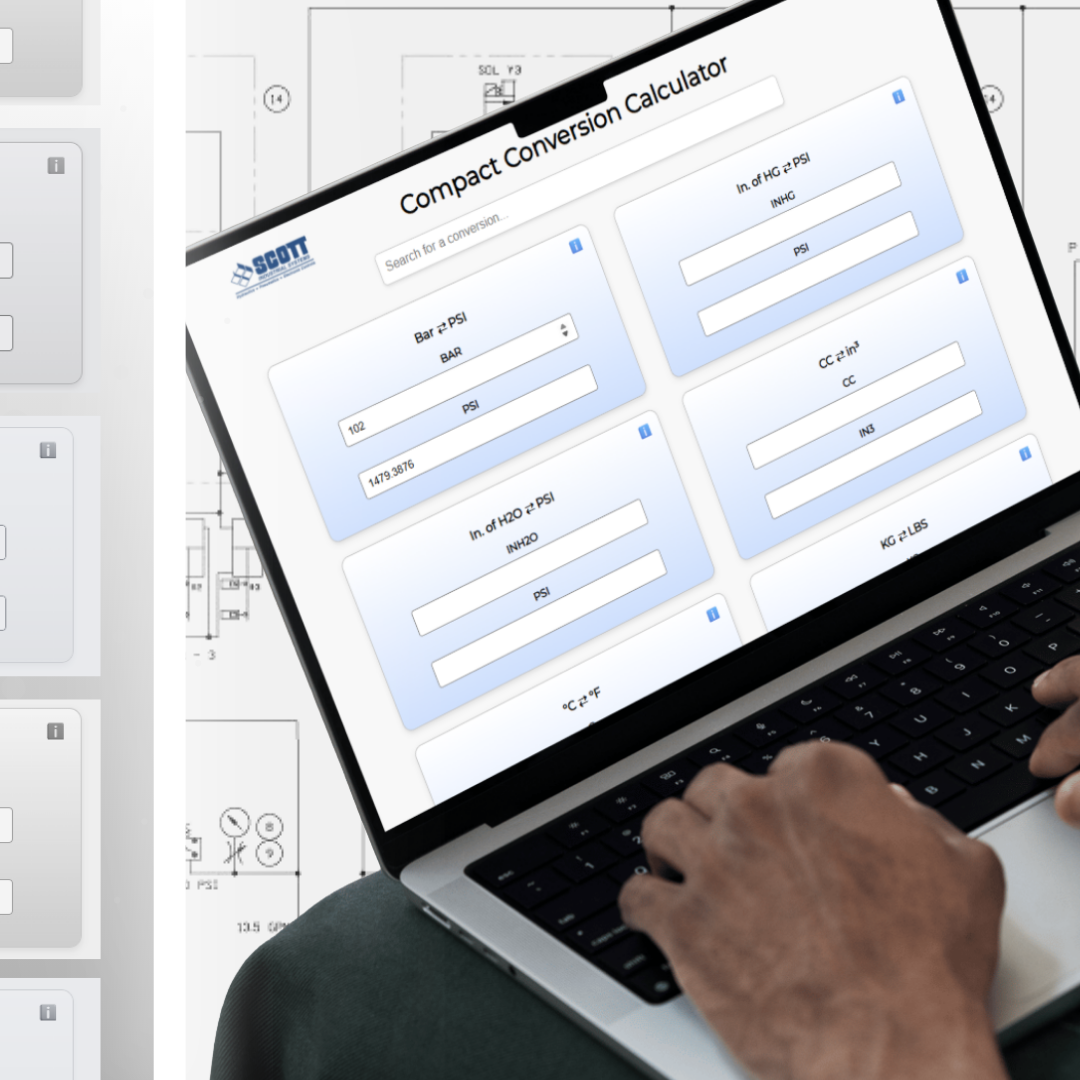

SCOTT delivers more than just components - we provide comprehensive fluid power solutions backed by rigorous testing, validation, and proven results.

👉 Ready to improve your hydraulic oil performance?

Contact our team today to learn more about our filtration solutions.

Contact our team today to learn more about our filtration solutions.

We replaced hydraulic guesswork with intelligent control. When a mobile vehicle-loading ramp raises nearly 10 feet, even small hydraulic inaccuracies can become a big problem. 👉 VIEW THE CASE STUDY This customer needed two cylinders to stay perfectly synchronized so safety ratchet teeth would land on the same position—keeping the machine square, safe, and structurally sound during vehicle loading. Traditional flow dividers (≈95–98% accurate) weren’t enough. Over a long stroke, that margin allowed misalignment well beyond the ratchet tooth spacing—leading to wear, premature bearing failures, and safety concerns. Our solution: A closed-loop electro-hydraulic control system using: ✔️ A Danfoss controller ✔️ Dual inclinometers ✔️ Proportional valves Instead of referencing gravity, the system maintains the ramp angle relative to the base, even on uneven terrain. Auto-leveling only activates during motion, includes multiple safety lockouts, and remains backward compatible with the existing fleet. The Results: ✔️ Ramp level maintained within ±0.25° ✔️ Accurate synchronization over a 10-ft stroke ✔️ Handles unbalanced loads ✔️ Reduced structural stress and long-term maintenance Sometimes the right answer isn’t more hydraulics - it’s smarter controls.

Scott Industrial Systems announces the acquisition of Automated Engineered Solutions (AES), an automation company headquartered in Oberlin, Ohio. This marks a significant milestone in SCOTT’s continued growth, deepening its expertise in industrial automation, custom machinery, & advanced engineering solutions.

Pneumatics have played a crucial role in the evolution of aviation, dating back to the early 20th century. By the 1920s and 1930s, as aircraft design advanced rapidly, pneumatic systems emerged as a practical solution for enhancing performance and reliability, especially when weight was a critical factor.

In today’s fast-paced manufacturing world, automation plays a crucial role in improving efficiency and reducing manual labor. Jasper Engines & Transmissions, a leader in remanufacturing powertrain components, faced a challenge in optimizing the removal of lifter plungers from a family of internal combustion engines.